BTMavrasya

VDL Klima's heat exchangers are used worldwide on board ships

Shipping and Maritime Industry

VDL Klima’s heat exchangers are used worldwide on board ships for the direct or indirect cooling of cooling water, (hydraulic) oil of, among other things, (electric) motors, generators, transformers and hydraulic systems. In addition to the traditionally used plate heat exchangers, the box cooler and POD cooler are increasingly used as a solution.

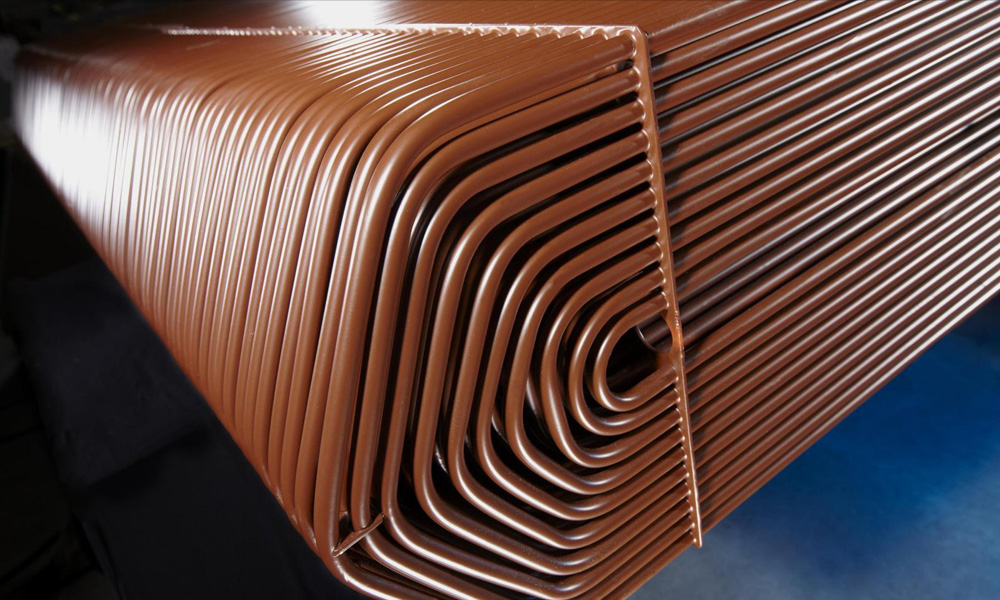

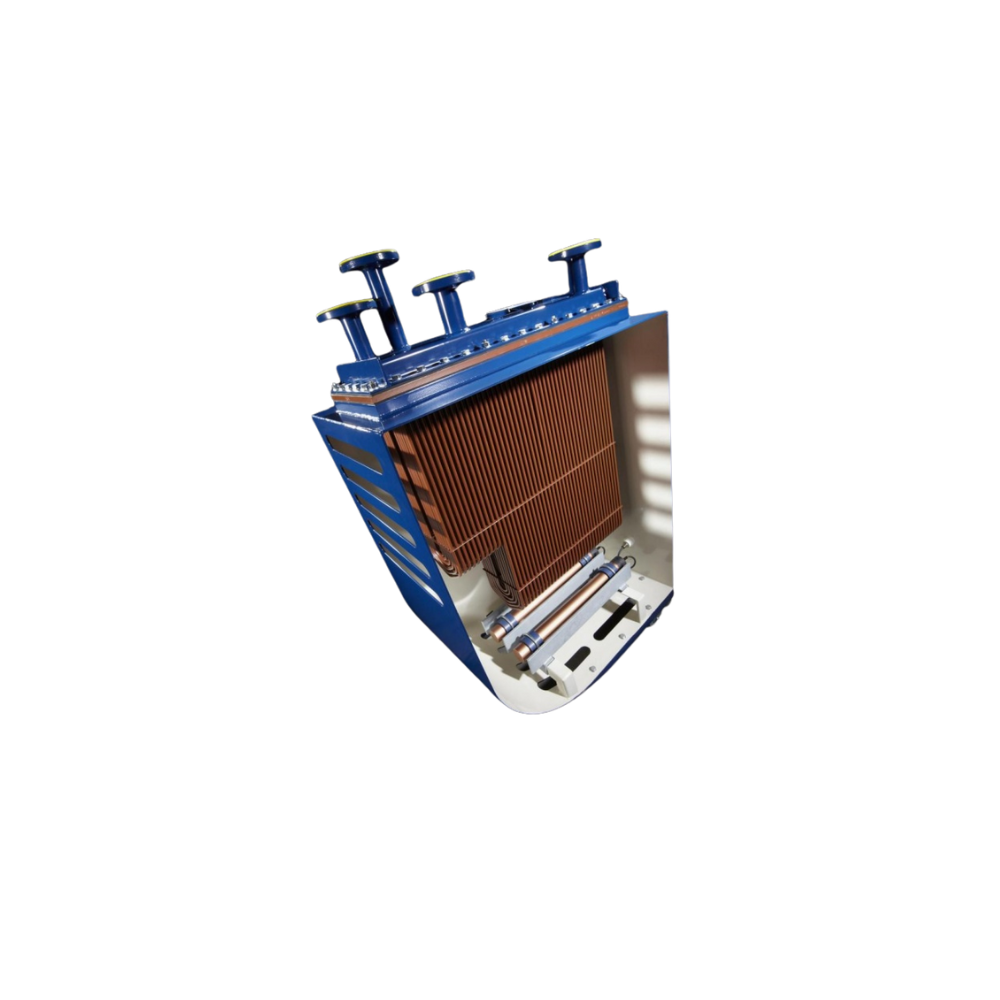

Box Cooler

The VDL Klima box cooler, with its compact design and large cooling capacity, is used on board ships to cool main engines, auxiliary engines and generator sets. The engine’s cooling water flows through a highly efficient V-shaped copper alloy tube bundle built into the vessel’s box cooler. Raw water flows over the tube bundle via slots at the top and bottom. The heat from the ship’s engine can thus be transferred into the open water. Water circulation is caused by the physical phenomenon of thermal siphoning: hot water rises and cold water falls. Impressed Current Anti-Fouling system (ICAF) Although the Klima box cooler requires little maintenance, the constant exposure to seawater will cause a build-up of algae and shellfish. Such biological growth has a negative effect on heat transfer. The highly effective ICAF system can prevent this.

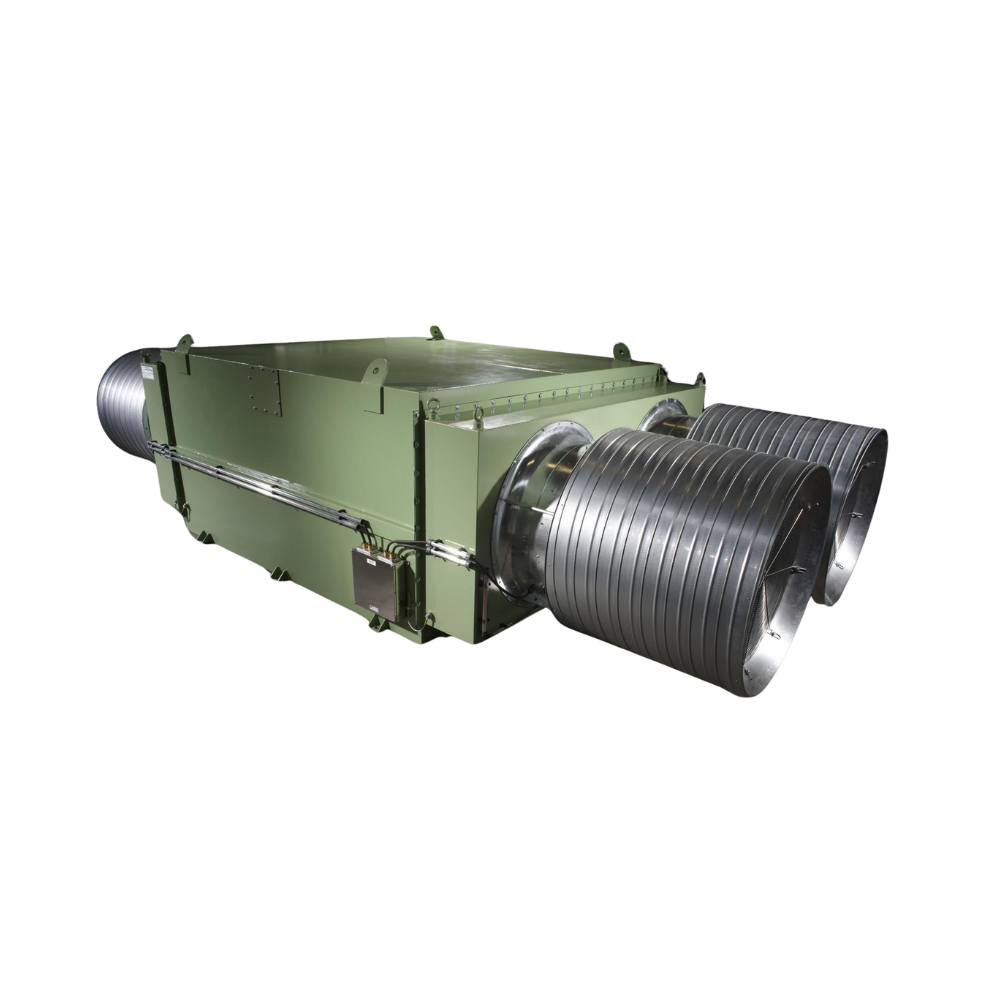

Air-to-Air Coolers

Air-to-air coolers (TEAAC, CACA) are often used for cooling generators or motors in places where cooling water is not or insufficiently available. As the name implies, an air-to-air cooler cools the closed air circuit of the generator/motor with a secondary air circuit, or outside air. Our air-to-air coolers can operate under different conditions. When developing our coolers, we take into account the thermal and mechanical requirements, as well as other requirements such as noise and pollution levels, environmental, seismic and acoustic conditions. Both an air-to-water and air-to-air cooler guarantee a consistently high level of efficiency of the machine to be cooled and extend the life of this machine by excluding polluting environmental factors.

Air-to-Water Coolers

Air-to-water coolers (TEAWC, CACW) are used for various applications such as for the cooling of electric motors, generators, transformers and converters. Where water is available and normal surface cooling is not possible, an air-to-water cooler is a logical choice. With an air-to-water cooler, the internal (closed) air circuit of the machine is cooled by a secondary water circuit. Our air-to-water coolers can operate under different conditions. When developing our coolers, we take into account the thermal and mechanical requirements, as well as other requirements such as noise and pollution levels, environmental, seismic and acoustic conditions. Both an air-to-water and air-to-air cooler guarantee a consistently high level of efficiency of the machine to be cooled and extend the life of this machine by excluding polluting environmental factors.

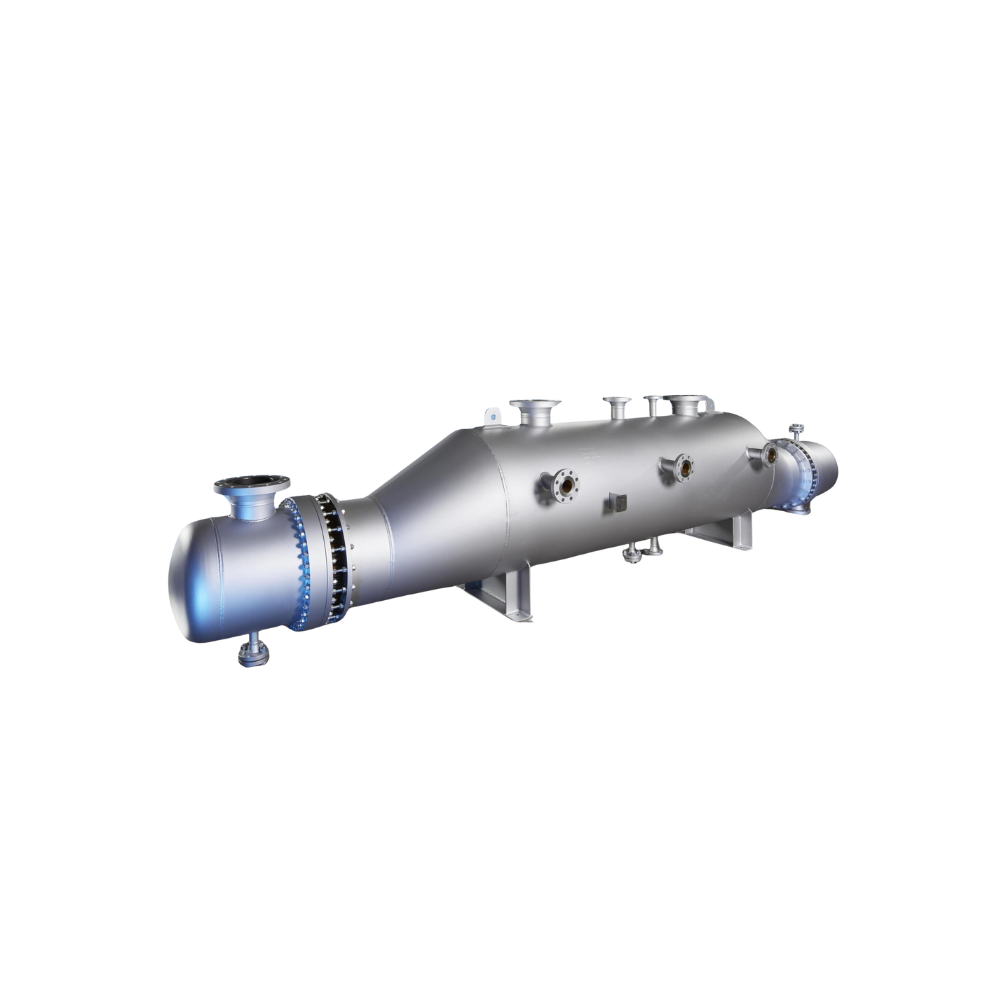

Tube Heat Exchangers

Tube heat exchangers account for 85% of the new heat exchangers supplied to oil refineries, chemical companies, petrochemical companies and energy companies. This is because this type of heat exchanger can be used for almost any application with a very wide range of temperatures, pressures and materials. In addition, the design methods and mechanical codes have been established on the basis of many years of experience. The VDL Klima tube heat exchangers can be used in almost all systems. We also supply tube heat exchangers for the food industry (e.g. for cleaning installations), for factories and offices (for hot water supply (tap water), central heating systems) and for the process industry (e.g. for coupling heat and power, process heating or process cooling and heat recovery). A tube heat exchanger consists of a jacket with an inner bundle. This heat exchanger is used to exchange heat and cold between liquids and gases. To transfer heat between the two liquids, one medium flows through the jacket and the other medium through the tubes.